| Western Lumber Co. Plywood Plant Photos Page #1 |

|

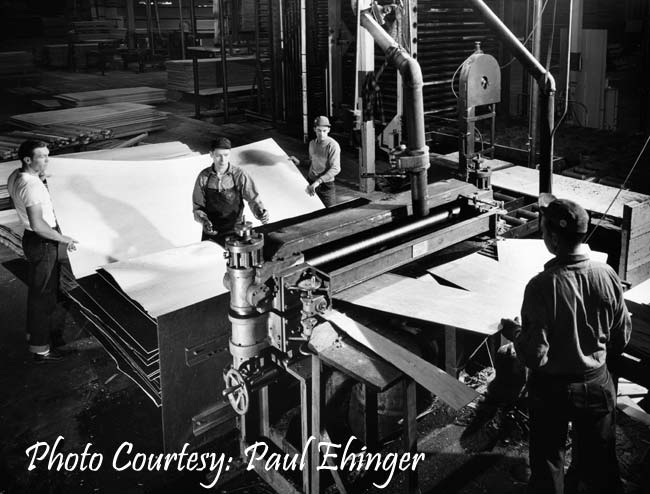

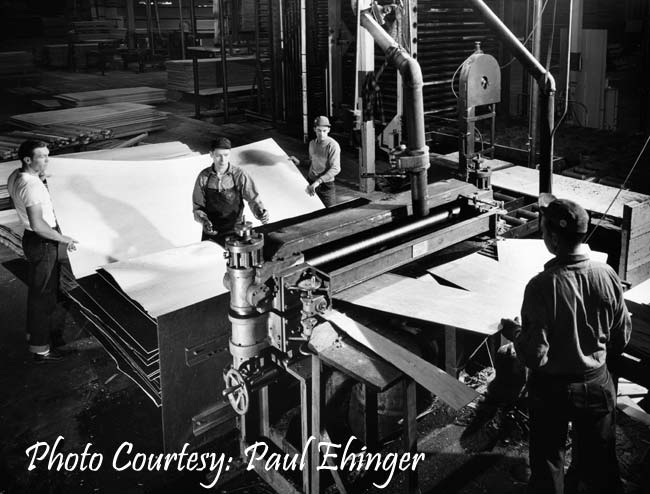

then is ejected from the other side of the Moore Dryer. |

|

. |

|

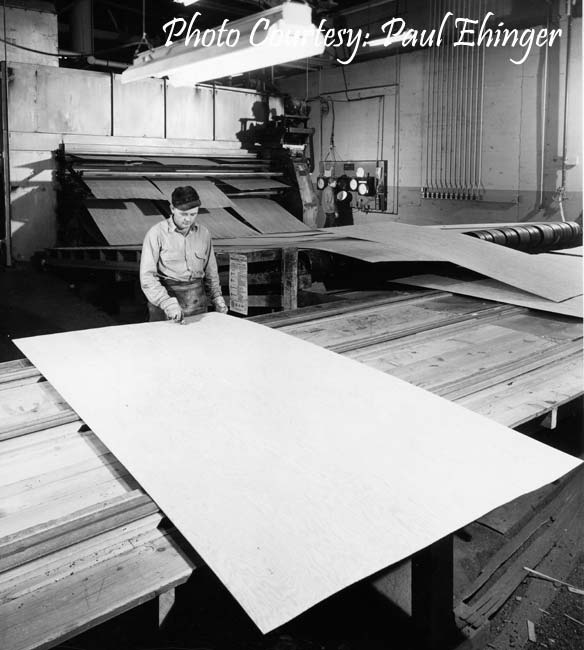

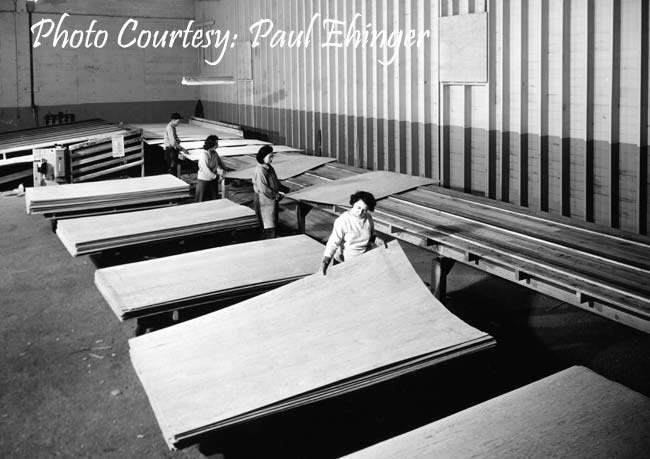

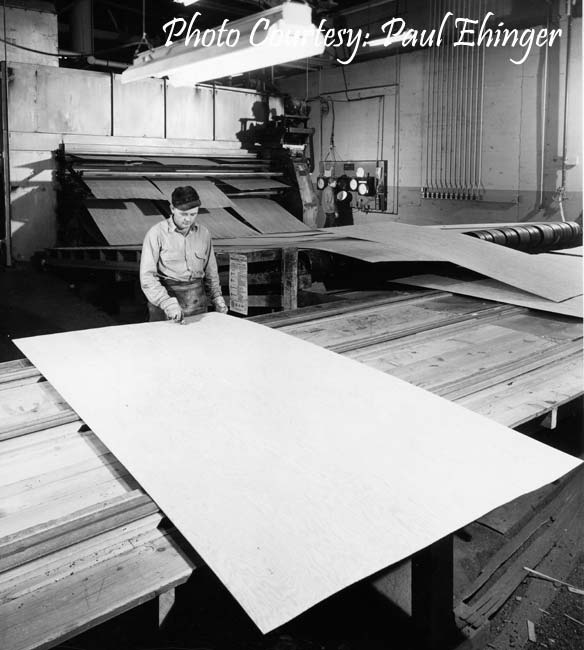

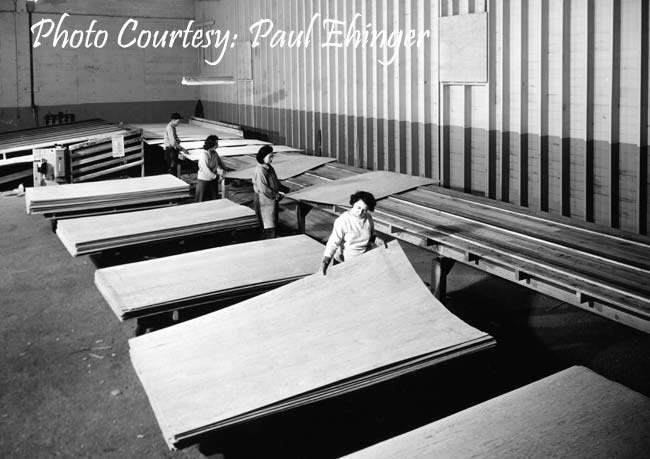

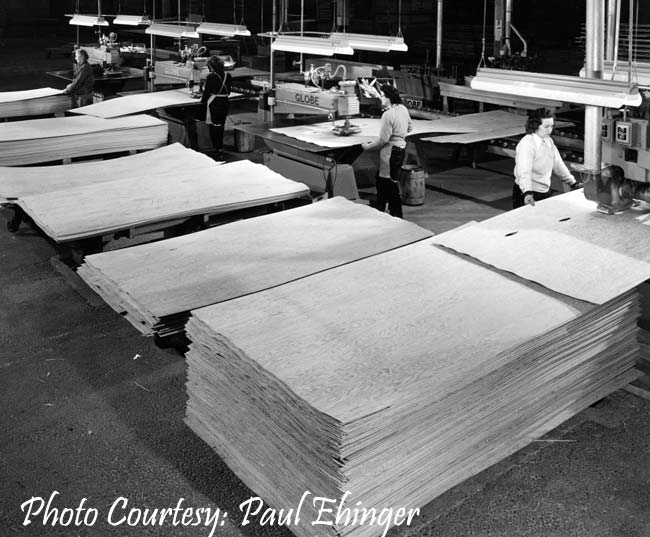

removing knots and other blemishes before being sent to the press |

|

. |

|

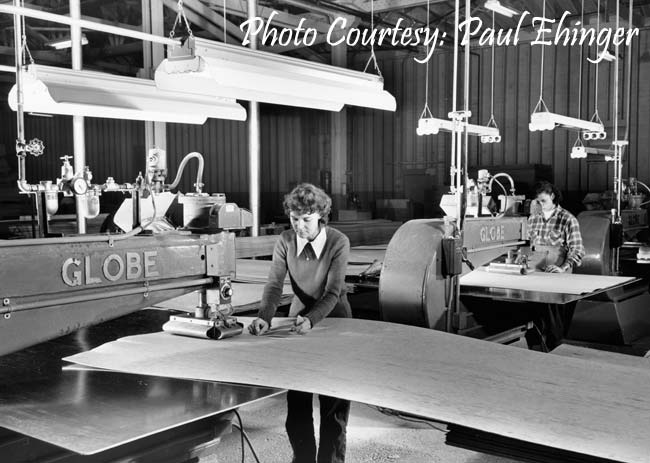

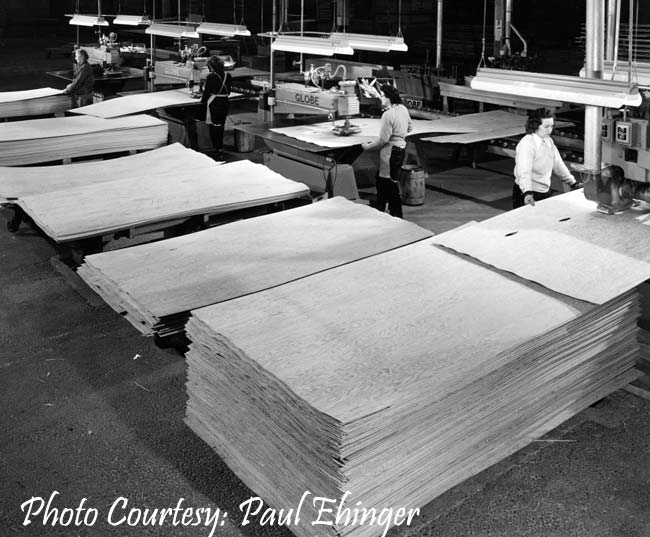

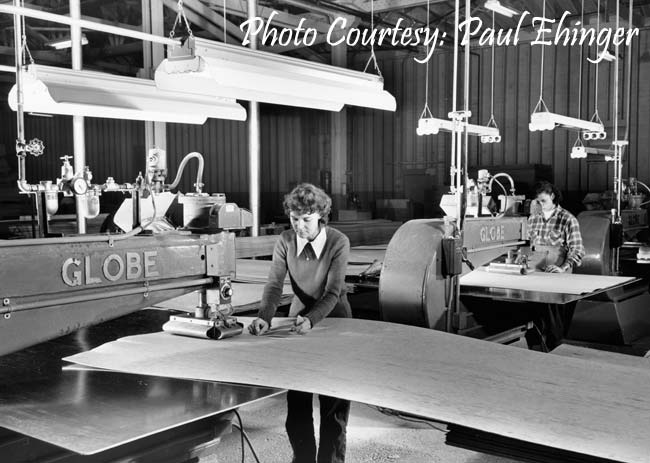

This machine coats narrows strips of veneer with resin, |

| Western Lumber Co. Plywood Plant Photos Page #1 |

|

then is ejected from the other side of the Moore Dryer. |

|

. |

|

removing knots and other blemishes before being sent to the press |

|

. |

|

This machine coats narrows strips of veneer with resin, |