| Tunnel #7 |

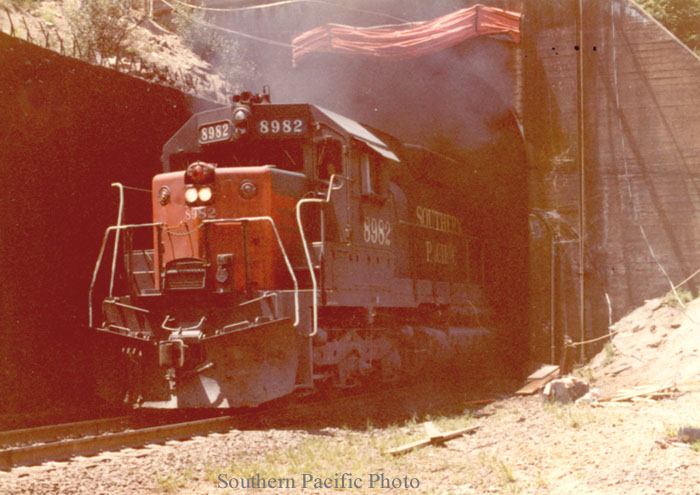

West portal, Tunnel #7.

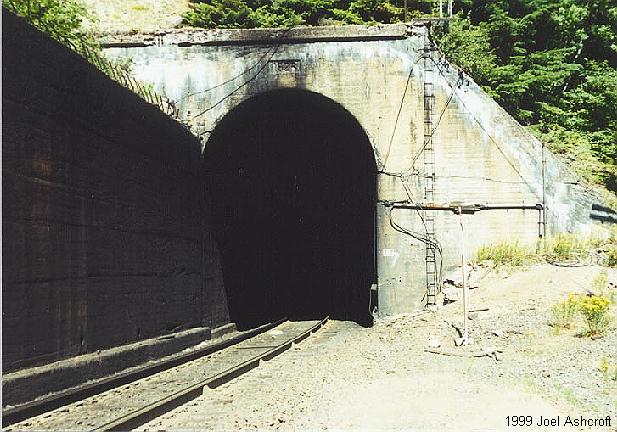

East portal, Tunnel #7.

ICC Valuation Report

Statement showing property changes from September 1, 1926, to December 31, 1927 |

||||||

line |

Character of property and description |

Date |

Units |

Number of |

Cost/unit |

Total |

| 1 | Account No. 5 Title Tunnels and Subways | |||||

| 2 | Tunnel No.7 MP 547.1 Single Track Driven | |||||

| 3 | Total Length 3164 ft. (sta. "G" 829+73 to "G" 798+09) | |||||

| 4 | Lined Length concrete-153 ft. per plans 18653 & C.S.347 | |||||

| 5 | Lined Length timber-2964 ft. | |||||

| 6 | Two concrete portals, plans 18247,40485 & 40487 | |||||

| 7 | Excavation-solid rock | Cu Yd | 61,965 | 3.70 | 229,271 | |

| 8 | Excavation-solid rock (invert) | " | 82 | 2.50 | 205 | |

| 9 | Portal backfill-common | " | 25 | .24 | 6 | |

| 10 | Portal backfill-Loose rock | " | 10 | .49 | 5 | |

| 11 | Overhaul | Cu Yd Sta | 42,776 | .0125 | 535 | |

| 12 | -Lining- | |||||

| 13 | ...Reinforced concrete | 1926 | Cu Yd | 592 | 13.00 | 7,696 |

| 14 | ...Plain concrete | " | " | 185 | 11.50 | 2,128 |

| 15 | ...Plain concrete (In invert) | " | " | 75 | 11.50 | 863 |

| 16 | ...Timber-untreated fir | " | m.b.m. | 1292.241 | 40.00 | 51,690 |

| 17 | ...Timber-Redwood | " | " | 38.935 | 45.00 | 1,752 |

| 18 | Packing-cordwood | " | cord | 1019 | 7.00 | 7,133 |

| 19 | Reinforcing bars | " | lbs. | 39,894 | .04 | 1,596 |

| 20 | Iron | " | " | 9,763 | .05 | 488 |

| 21 | Creosote paint | " | gallon | 851 | .70 | 596 |

| 22 | Tunnel Sign-C.S. 9 | " | Each | 2 | 1.00 | 2 |

| 23 | Pump fire extinguisher (5 gallon Pyrene) | 1927 | " | 2 | 20.00 | 40 |

| 24 | Fire Ladders 24 ft. | " | " | 2 | 6.00 | 12 |

| 25 | Fire Ladders 16 ft. | " | " | 1 | 4.00 | 4 |

| 26 | Fire barrels & covers-concrete | " | " | 4 | 5.00 | 20 |

| 27 | Fire buckets-metal, cone shaped | " | " | 8 | .25 | 2 |

| 28 | Patrol Fire Extinguisher 2-1/2 gal. | " | " | 2 | 10.50 | 21 |

| 29 | Axes, single bitt | " | " | 2 | 1.00 | 2 |

| 30 | ..........Total | $404,391.08 | ||||

| 31 | ..........Interest during construction | $22,157.92 | ||||

| 32 | ..........Final | $426,549.00 | ||||

West Portal Tunnel Curtain

Completed curtain about to begin testing.

An interesting fact about tunnel #7 was the tunnel curtain that was built at the west portal to reduce overheating locomotives. This curtain, however; proved to be a $42,125.00 loss after it failed to open as a westbound freight approached. The train ripped through the canvas curtain and it was never rebuilt. Below is a letter submitted to the Oregon Divison superintendent.

Mr. A. D. DeMoss:Operating Department is having a serious problem with SD-45 locomotives heating up coming through the tunnels on the Cascade Line. Mr. Jaekle has discussed with us, and it has been decided to make an experimental installation of a flexible curtain at the upper portal of Tunnel 7, Cruzatte, to increase the flow of air passed the first and second units to the third unit of each consist. The curtain will be raised just before the lead locomotive reaches the upper portal. A local Canvas and awning shop in Eugene has been contacted, and they have offered to make up the curtain of 18 oz vinyl-coated nylon complete with grommets and nylon rope per attached requisition and sketch for $298.16. Since Operating Department is having to reduce the tonnage of each train during the summer temperatures to prevent locomotives overheating and shutting down, it is important that we test out the curtain without delay. Would appreciate your placing purchase order with the Eugene firm as soon as possible. H.M. Williamson

|

Once approved, Eugene Canvas Products constructed a 16'9" x 24' 18 oz vinyl coated nylon curtain complete with grommets, 1 1/2" rings, and nylon rope. The curtain was driven by an electric motor wired to the track circuits placed 400 ft. from the curtain. When a train passed over the circuits, the curtain would raise and then close after the train's passage. The curtain was felxible so that no damage to a train would result if it was struck. In addition, an emergency push-button was attached to the circuit for manual operation to prevent personnel from becoming trapped in the tunnel.

The following letter reflects the test results:

Road tests have been completed to evaluate the effectiveness on locomotive performance and train speeds of a temporary curtain applied to the west portal of Tunnel #7 near Cruzatte.Eight runs were made between June 14 and June 23 utilizing SD-45 unit 8921 as the trailing unit of a 3-unit lead locomotive consist. Train speeds were adjusted by throttling back helper units striving for 12.5 MPH nominal on grade. Four runs were conducted with curtain closed and four were run with curtain open. Data collected are tabulated and graphed on the attached exhibits. The graphs have been colored only in the confines of Tunnel #7. Unit 8921 was equipped with a temperature recorder mounted in the cab of the unit to log critical engine temperatures. Horsepower meters were also installed to measure changes in engine output as unit progressed through the tunnels. The Curtain used was a temporary affair made of rubberized nylon sheet and, while it did not offer a perfect seal, it did demonstrate the effect of pressurizing the tunnel by the piston action of the locomotive. Pressures of four pounds per square foot against the curtain were recorded, and we understand that this pressure is within the design limitations imposed by FMC for construction of permanent curtain. For the first run with the curtain closed, Test #1, the curtain was opened at a point where the locomotive was within 600 feet of the tunnel exit. For all subsequent tests with the curtain, it was set to open at a 400 foot distance. There is no question but that the use of a curtain at Tunnel #7 will give marked improvement to locomotive performance. While the benefits to be gained in so far as reduction of engine temperatures are minimal, the supply of oxygen-rich air for engine combsution greatly reduces the amount of engine derating which normally occurs in tunnels and consequently train speeds are kept to a reasonable minimum. At no time during the tests with the curtains in operation did train speed in Tunnel #7 get lower than 11 miles per hour, whereas, under standard conditions with curtain open, minimum speeds ranged between 4 and 8.5 MPH. At the conclusion of run #7 where train speed slowed to four MPH and measured engine output dropped to 250 HP, we were suspicious that unit 8921 had sustained a turbo charger malfunction. Unit was closely inspected on return to Eugene that evening, and, as it turned out, the only discrepancy found was that air filters appeared dirty and in need of changing. This condition of filter plugging may have had an influence on the relatively large amount of engine derating which occurred on the previous test #6 when curtain was in operation. In any event, the last test, which had the new engine air filters in service, produced excellent engine performance in that there was only a loss of 600 horsepower due to derating and no change in train speed through the tunnel. It is our considered opinion that use of a curtain at west portal of Tunnel #7 will greatly improve performance of high horsepower units in that territory and will maintain train speeds at a level considered acceptable by operating crews. Recommend that we proceed with FMC to have permanent doors applied. As matter of information, the proposed tunnel tests utilizing SD45T-2 units to be conducted jointly with EMD are scheduled to commence instrumentation on July 10 with the first trip from Sparks to Roseville to be on July 18. At the conclusion of these tests, which include two runs through the Cascades starting on or about July 22, we intend to utilize EMD's test car ET-800 to evaluate the performance of outside shrouds over radiator air intakes together with 6th throttle knockdown feature on SD-45 units with all units in the lead helper consists so equipped. W.O. Brown

|

|

|

Tunnel Curtain Tests

Cascade Tunnel #7 - Unit 8921 Operating as 3rd Unit of Lead Consist | ||||||||

| Test No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 6/14/72 With Curtain (1) | 6/15/72 Without Curtain | 6/16/72 With Curtain (2) | 6/17/72 Without Curtain | 6/21/72 Without Curtain | 6/22/72 With Curtain(2) | 6/22/72 Without Curtain | 6/17/72 With Curtain(2) | |

| Max. Water Temp. | ||||||||

| Entering Tunnel | 200 | 194 | 193 | 192 | 190 | 197 | 181 | 180 |

| Leaving Tunnel | 242 | 226 | 232 | 230 | 238 | 233 | 222 | 230 |

| Max. Lube Oil Temp. | ||||||||

| Entering Tunnel | 210 | 204 | 204 | 207 | 200 | 205 | 188 | 190 |

| Leaving Tunnel | 242 | 228 | 235 | 233 | 240 | 236 | 223 | 228 |

| Radiator Air Temp. | ||||||||

| Entering Tunnel | 98 | 83 | 130 | 90 | 70 | 82 | 71 | 60 |

| Leaving Tunnel | 156 | 205 | 199 | 206 | 190 | 188 | 191 | 185 |

| Engine Air Temp. | ||||||||

| Entering Tunnel | 111 | 111 | 111 | 114 | 106 | 114 | 90 | 77 |

| Leaving Tunnel | 195 | 196 | 183 | 199 | 203 | 209 | 203 | 195 |

| Engine Horsepower | ||||||||

| Entering Tunnel | 3140 | 2470 | 2820 | 2670 | 2940 | 2810 | 1850 | 3160 |

| Minimum in Tunnel | 2570 | 1230 | 1740 | 1290 | 1300 | 1610 | 250 | 2550 |

| % HP reduction | 18.1 | 50.2 | 38.3 | 51.6 | 55.7 | 42.6 | 86.5 | 19.3 |

| Train Speed | ||||||||

| Entering Tunnel | 12.0 | 11.0 | 10.5 | 10.5 | 12.5 | 11.5 | 9.0 | 12.5 |

| Leaving Tunnel | 11.0 | 8.5 | 11.0 | 8.0 | 8.0 | 11.0 | 4.0 | 12.5 |

| % Change in Speed | -8.2 | -22.7 | +4.7 | -23.8 | -36.0 | -4.3 | -55.5 | 0 |

| Time in Tunnel-seconds | 180 | 215 | 190 | 240 | 225 | 172 | 246 | 166 |

|

|

|